Fig. 1: Examples of multi-DOF hinge joints embedded on miniature tubes by on-axis laser machining. From the left, an 8 mm diameter EndoWrist arm used in the da Vinci surgical robotic system (added for the size comparison), a 5 mm diameter stainless steel tube with 2-2 orthogonal hinge joints, a 1.27 mm diameter NiTi tube with 3-3 orthogonal hinge joints, and a 1.27 mm diameter NiTi tube with 1-1 orthogonal hinge joints.

With the proliferation of successful minimally invasive surgical techniques, comes the challenge of shrinking the size of surgical instruments further to facilitate use in applications such as neurosurgery, pediatric surgery, and needle procedures. This paper introduces laser machined, multi-degree-of-freedom (DOF) hinge joints embedded on tubes, as a possible means to realize such miniature instruments without the need for any assembly. A method to design such a joint for an estimated range of motion was explored. The effects of design and machining parameters on the mechanical interference, range of motion, and joint dislocation were analyzed. The extent of interference between the moving parts of the joint can be used to predict the range of motion of the joint for rigid tubes and future design optimization. The total usable workspace was also estimated using kinematic principles for a joint in series and for two sets of orthogonal joints. Our work can open up avenues to a new class of miniature robotic medical devices with hinge joints and a usable channel for drug delivery. [1]

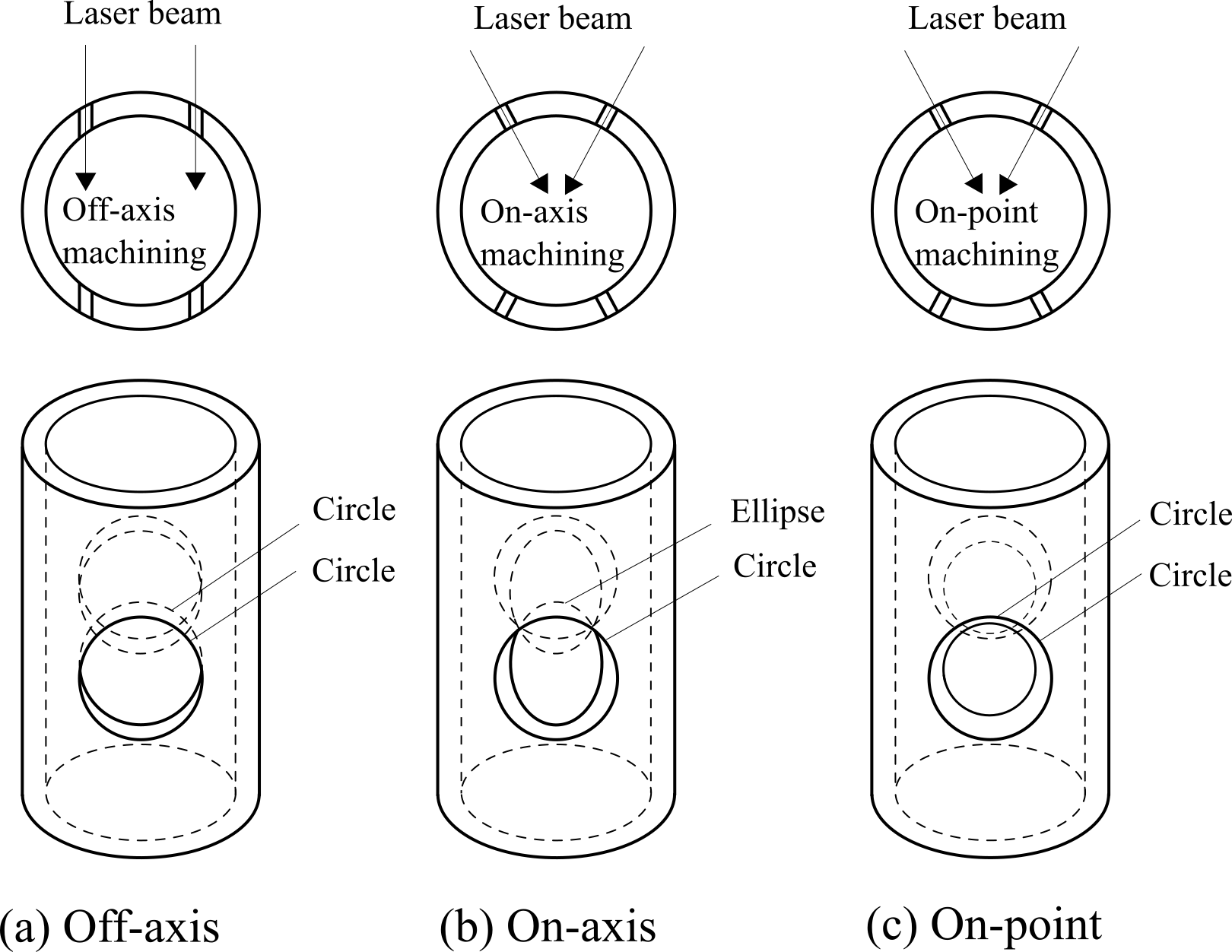

Fig. 2: Comparison of (a) off-axis, (b) on-axis, and (c) on-point machining for cutting hinge joints. Different hinge geometries can be achieved by suitably directing the laser beam. On-axis and on-point machining result in the formation of a wedge that prevents the hinge from moving into the workpiece. This wedging action can secure the hinge against lateral dislocation when machined on both sides of the workpiece. In this paper, on-axis machining is examined.